Roofing PVC Polyvinyl Chloride Waterproofing Membrane Sheet Polyester Reinforced

Description

Basic Info

| Model NO. | PVC 029 |

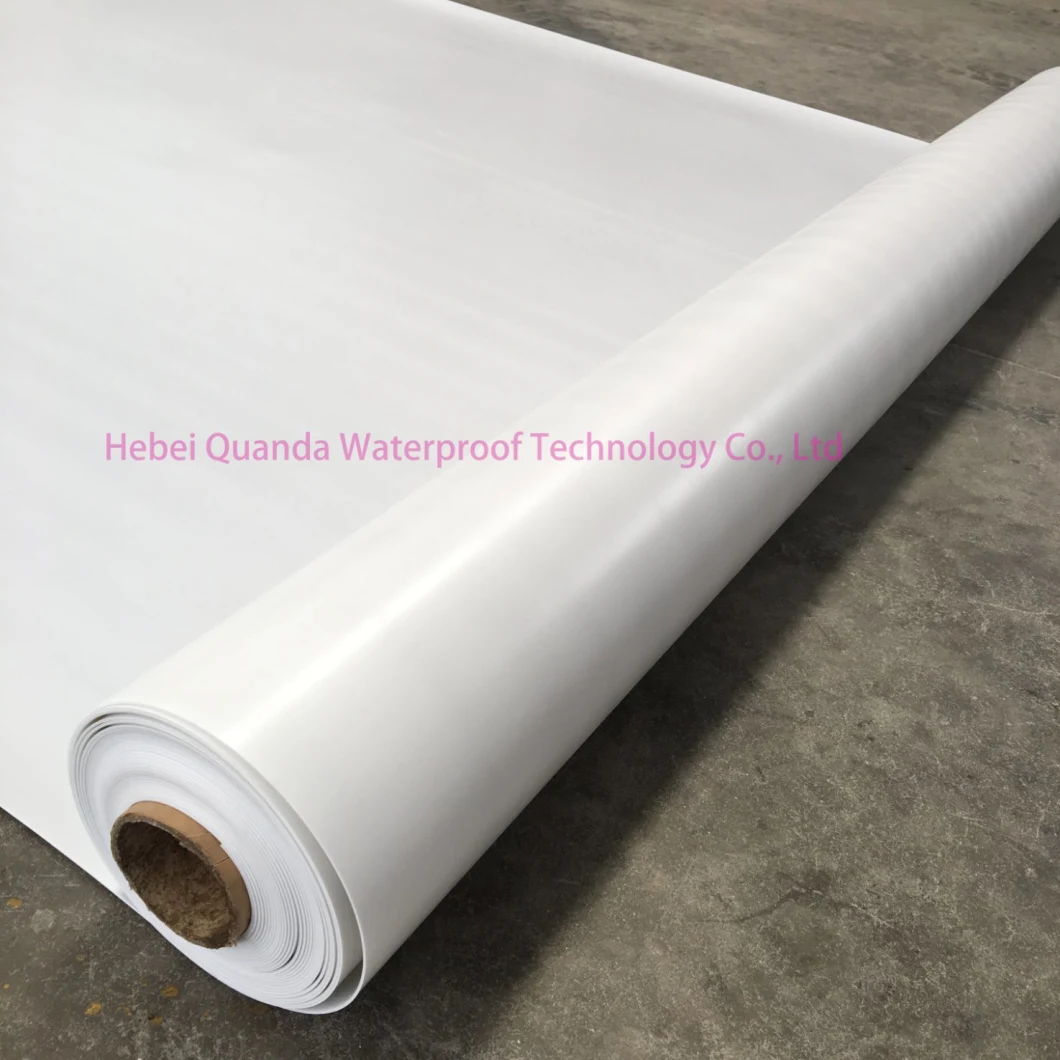

| Ceiling Tile Shape | Roll |

| Material | PVC |

| Thickness | 1.5mm |

| Ceiling Tile Type | PVC Ceilings |

| Surface Treatment | Smooth |

| Function | Anti-static, Fireproof, Heat Insulation, Sound-Absorbing, Waterproof |

| Certification | ISO, CE |

| Color | White |

| Usage | Outdoor |

| Quality | Exposed Type, Non-Vulcanized |

| Transport Package | Ocean Shipping |

| Specification | 1.2mm 1.5mm 2.0mm thickness |

| Trademark | Xingshidun |

| Origin | China |

| HS Code | 4008210000 |

| Production Capacity | 200000 M2/Day |

Packaging & Delivery

Package size per unit product 38.00cm * 25.00cm * 100.00cm Gross weight per unit product 65.000kgProduct Description

PVC roofing waterproof membrane

1.2mm, 1.5mm, 1.8mm,2.0mm PVC waterproof membrane

Product Description

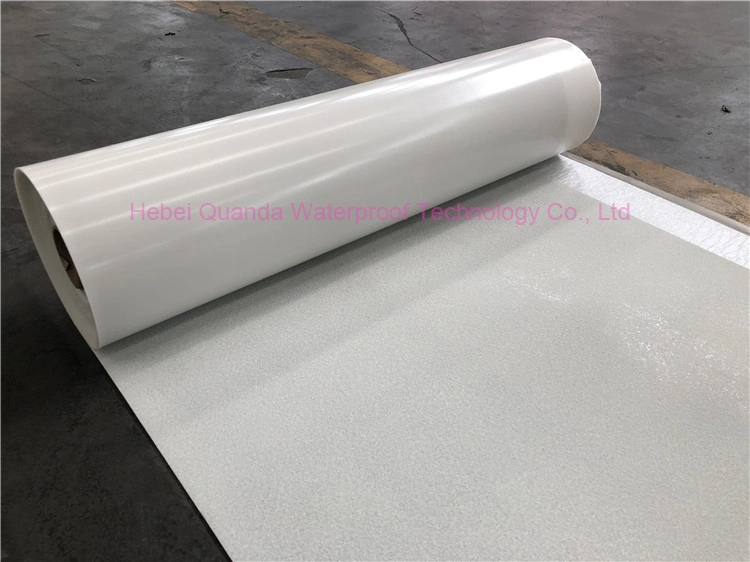

PVC waterproof membrane is made from ternary ethylene-propylene rubber, which is designed for waterproofing of exposed and non-exposed applications, adopted the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology. PVC waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

| Thickness(mm): | 1.2, 1.5, 1.8, 2.0 |

| Allowable deviation(%): | -10 to +15 |

| width(mm): | 1000, 1200 |

| Square meter (m2) / roller: | 20, 24 |

| The specifications can be customized by the buyers' requirments. | |

Type: PVC Membrane with PVC-L,PVC-H,PVC-P

Specification:

| No. | Items | JL1 | JL2 | |

| 1 | Tensile Strength (MPa) | 23ºC | ≥7.5 | ≥4.0 |

| 60ºC | ≥2.3 | ≥0.8 | ||

| 2 | Breaking Elongation | 23ºC | ≥450% | ≥400% |

| -20ºC | ≥200% | ≥200% | ||

| 3 | Tear Strength kN/m | ≥25 | ≥18 | |

| 4 | Impermeability, 0.3Mpa, 30 minutes | No leaking | No leaking | |

| 5 | Low Temperature Flexibility | -40ºC | -30ºC | |

| 6 | Thermal Stability (mm) | Extend | ≤2 | ≤2 |

| Shrink | ≤4 | ≤4 | ||

| 7 | Hot Air Aging (80ºC×168h) | Tensile Retention | ≥80% | ≥90% |

| Breaking Elongation Retention | ≥70% | ≥70% | ||

| 8 | Alkali Resistance, Saturated Ca(OH)2 Solution, 23ºC×168h | Tensile Retention | ≥80% | ≥80% |

| Breaking Elongation Retention | ≥80% | ≥90% | ||

| 9 | Ozone Aging(40ºC×168h) | Elongation 40%, 500pphm | No crack | No crack |

| 10 | Artificial Weathering Aging | Tensile Retention | ≥80% | ≥80% |

| Breaking Elongation Retention | ≥70% | ≥70% | ||

| 11 | Bonding Peel Strength (Sheet and Sheet) | N/mm (Standard Test Conditions) | ≥1.5 | ≥1.5 |

| Soaking Retention Rate(23ºC×168h) | ≥70% | ≥70% | ||

Features:

1) Good weather fastness and dimensional stability.

2) Excellent performance to high and low temperature (-40ºC ~ +80ºC), UV resistant and anti-corrosion.

3) Higher tensile strength and better extensibility under normal construction conditions.

4) Easy installation, solid joint, and no environmental pollution.

5) Good rooting penetration resistance.

Application:

1) Roofs, basement, toilet, bridge, underground, tunnel and dam.

2) Industrial and civil building waterproof.

3) Geo-synthetic liner for swimming pool, channels, irrigation system.

4) Especially for projects with high requirements in durability, anti-corrosion and deformation.

Construction Method:

1). Ensure all surface are clean,dry and dust-free. Remove any loose particles and any rust with a wire brush & soft broom.

2).Roll out the membrane.

3).Remove the backing paper and place the adhesive side to the previously prepared surface.

4).To ensure a tight contact-smooth the tape down with a dry cloth, remocing all the air bubbles;

5).Press the tape to the surface firmly once in position.

6).Smooth flat all edages with a wallpaper roller or trowel.

7).After use reseal pack and store upright in cool,dry condition.

Storage and Transportation:

1) Waterproof materials should be stored under dry and ventilated conditions.

2) Different types of membranes must be piled separately.

3) Under usual condition, storage period is one year since production date.

4) Waterproof materials should be put vertically during transportation.

5) It should be kept away from sunshine and rainwater.

6) Transport and storage process should be away from the fire source, storage temperature does not exceed 35 ºC, the storage period is 1 year.

Prev: Impact Resistance Easy Install Manufacturers Corrugated Plastic PVC UPVC Roof/Roofing Sheets

Next: Thermal Insulation Colorful Hollow Plastic UPVC Roofing Tile PVC Roof Sheet for Warehouse

Our Contact